Process Safety Assurance Benchmarking - Oil & Gas

For over 24 years, Fulcrium's benchmarking has helped Process Safety Assurance group functions within Oil & Gas to design and drive transformative, best-in-class agendas.

Fulcrium's benchmarking helps future-proof Process Safety Assurance functions by Transforming their Strategy, Vision, Purpose and Organisation

For 24 years, Fulcrium benchmarking has been assisting frontline and second line assurance organisations to transform their Strategy, Vision, Purpose and Performance so they can future-proof the Process Safety Assurance function.

Since the 1960s the global oil and chemical sectors have led the way in process safety management. Our expertise in Oil & Gas Process Safety Assurance Benchmarking over more than two decades has been developed primarily in this sector and is, we believe, best-in-class.

Other complex industries have similar hazard profiles to oil, gas and chemical, including pharmaceutical, explosives, mining, nuclear, engineering and transport.

Despite widespread adoption of safety management systems, major incidents continue to occur, albeit at very low frequency.

When they do, their impact is substantial: fatalities and serious injuries, and damage to the environment, company reputations, assets and operating capabilities.

Supermajor Partners with Fulcrium for Process Safety Assurance Benchmarking

Fulcrium was appointed by the in-house specialist assurance function accountable for second line Process Safety Assurance at a Supermajor.

The brief was to undertake a wide-ranging benchmarking engagement comparing the frontline and second line strategy, systems, processes, organisation, risk, policies, standards, governance and assurance activities of the function with those of peers at IOCs, NOCs and service companies.

Part of the brief was to provide tangible evidence of what constituted a world class Process Safety Assurance function and how such insights could translate into transformational value for the function in its support of Drilling & Completions, Reservoir & Wells, Major Projects and Operations & HSSE. Fulcrium was also required to assist the client with a renewed vision and roadmap to transform the function.

The Client’s Verdict:

Following an extensive evaluation of the benchmarking market for Process Safety Assurance providers, we appointed Fulcrium to conduct benchmarking and assist us with our thinking to future-proof our organisation.

No benchmarking firm that we encountered can match it for extent of reliable data, methodology or, more importantly, for Process Safety Assurance domain specificity in the upstream and downstream oil and gas industry.

Fulcrium brought extensive. high quality data that informed genuinely new and impactful insights which have helped us shape our Process Safety Assurance function.

Fulcrium's benchmarking helps future-proof Process Safety Assurance functions by Transforming their Strategy, Vision, Purpose and Organisation

- Strategic and functional excellence of oil & gas frontline operations and, second line & third line Process Safety Assurance organisations.

- Our Oil & Gas Process Safety Assurance Benchmarking covers every aspect that could contribute to a failure (process, plant, procedures and people)

- Hazard identification in high-risk, and lower-risk non-critical systems.

- Risk assessments of e.g. tasks, human reliability, environments, physical infrastructure, EC&I systems, other assets.

- Compliance with regulations, standards and guidance to avoid improvement or prohibition notices, or prosecution.

- Procedural and control systems analysis.

- Leadership and administration involved in policy-setting and deployment, audit and review, and the management of change.

- Organisational improvement systems and indicators.

We assist the world’s largest hazard sector companies, with board-level outputs from our benchmarking

For 24 years, Fulcrium benchmarking has been assisting frontline and second line assurance organisations to transform their strategy, vision, purpose and performance so they can achieve best-in-class excellence.

Are you 100% sure that your major hazard process risks are effectively controlled by your frontline, second line and third line, or are you concerned that you rely on failure data and are not sufficiently proactive?

Our proprietary benchmarking pinpoints Process Safety Assurance opportunities during all stages, and proposes any required mitigation options. In several cases, this has resulted in dramatic improvements in optimising operating conditions in addition to improvements in risk control and quality systems.

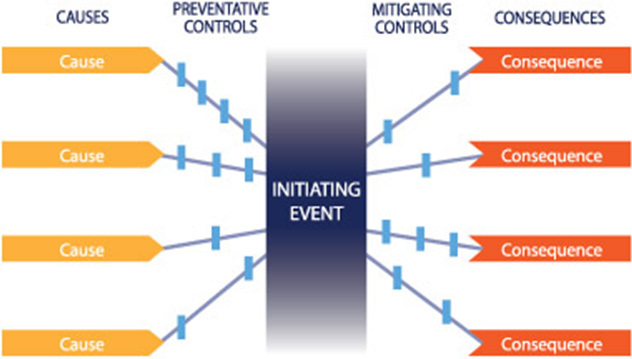

Major incidents rarely result from a single cause but rather by multiple failures that coincide and collectively result in an exceptional event with severe consequences.

We benchmark against industry best practice in the same or different high hazard sectors, regionally and globally, to deliver:

- Review of the full scope of leading and lagging indicators.

- Indisputable metrics for leverage and breakthrough frontline, second line and third line performance, and functional performance.

- Identification of serious value opportunities in risk mitigation, safety and quality.

- Maximum-impact on safety & operational risk culture.

INEOS Chemicals Chairman Sir Jim Ratcliffe talks to Fulcrium about Benchmarking-Driven Exceptional Performance

INEOS Chemicals founder and Chairman, Sir Jim Ratcliffe discusses:

- Process Safety Assurance Benchmarking

- Corporate and Commercial Benchmarking

- Petrochemicals Benchmarking

- Operational Performance Benchmarking

- Cost Benchmarking

- Upstream Oil & Gas Benchmarking

- Downstream Oil & Gas Benchmarking

- Value Chain Benchmarking

For best-in-class Process Safety Assurance Benchmarking to fulfil the goal of strategic, organisational and functional excellence contact us today.

'

'